Industrie 4.0

With regard to Industry 4.0, the IFL develops cyber-physical systems for intralogistics and is active at the supply chain management level.

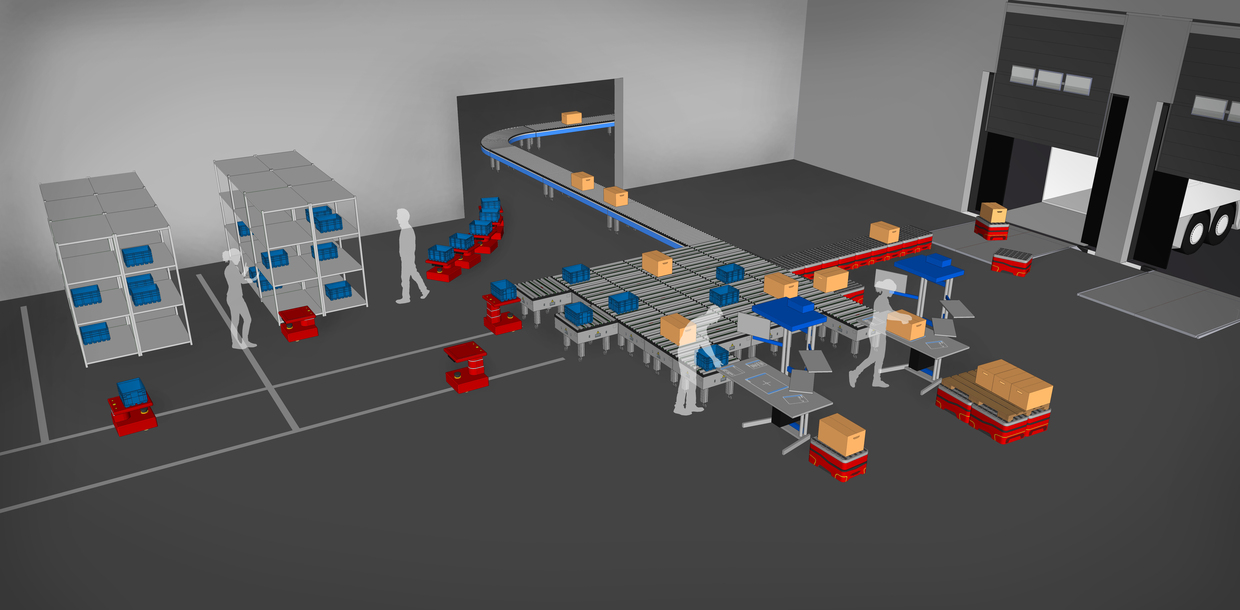

Plug&Play-material handling

The IFL has been conducting research on so-called Plug&Play-material handling technology for over 10 years: material handling technology, which is simple to set up and put into operation. The developed systems have the characteristics of cyber-physical systems, which are part of industry 4.0. Examples of this are the FlexFörderer, a modular and decentrally controlled conveyor system, the Gridsorter, a modular, high-density sorter and dFlow, an automated material delivery system. In the field of autonomous guided vehicles, there is KARIS PRO, an autonomous guided vehicles, FiFi, a gesture-controlled robot and KomRob, an autonomous picking vehicle.

Intuitive human-machine interaction

The human being is the focus of Industrie 4.0: Therefore, the IFL integrates new concepts such as gesture control or mobile human-machine interfaces into intralogistic systems. These human-machine interfaces are developed and tested in different projects. Examples include FiFi, a gesture-driven robot, the Arbeitsplatz 4.0, a gesture-controlled packing and assembly table with "table-based" interaction and KARIS PRO, in which human beings have access to the system control via mobile devices.

Control concepts

In order to ensure the efficiency of the developed intralogistics systems, the IFL also develops and implements control algorithms. The decentralized control of the FlexFörderer and GridSorters, the swarm intelligence of KARIS PRO or the forward-looking routing of a driverless transport system is worth mentioning.

IT-based support in supply chains

How can data and IT systems help to meet, in supply due to short term disturbances, the right decision in rescheduling? In the project ProveIT answers to these questions are sought.